Cheap Loaf Toast Bread Dough Molding Making Machine video link:https://youtube.com/shorts/3mKFID3kFhw?feature=share

Cheap Loaf Toast Bread Dough Molding Making Machine

Cheap Loaf Toast Bread Dough Molding Making Machine introduction:

1. According to different bread requirements, the spacing of the pressing plate can be adjusted to control the rolling length of the dough

2. The surface of the pressure roller is treated with hard chrome plating,which is not easy to be scratched

3. Stainless steel baffle, non-stick surface, easy to clean

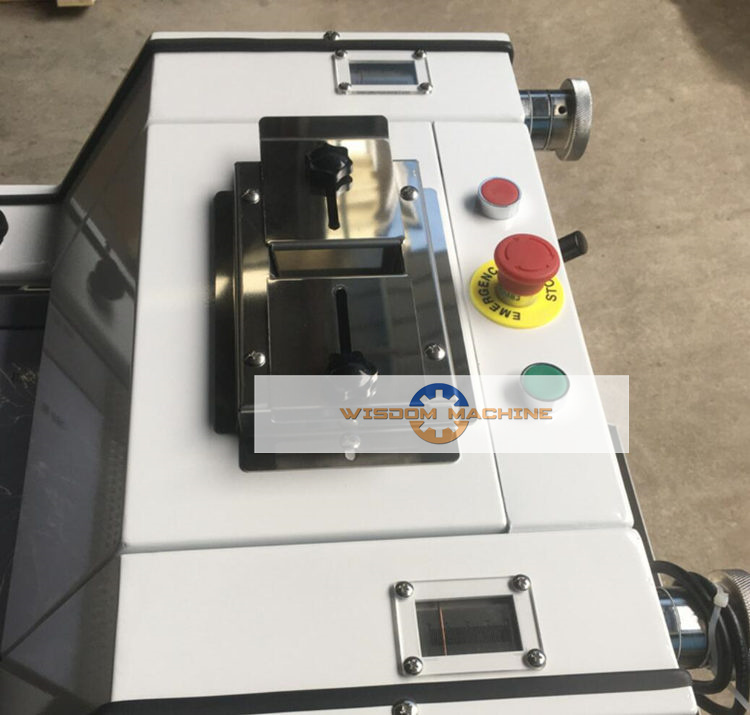

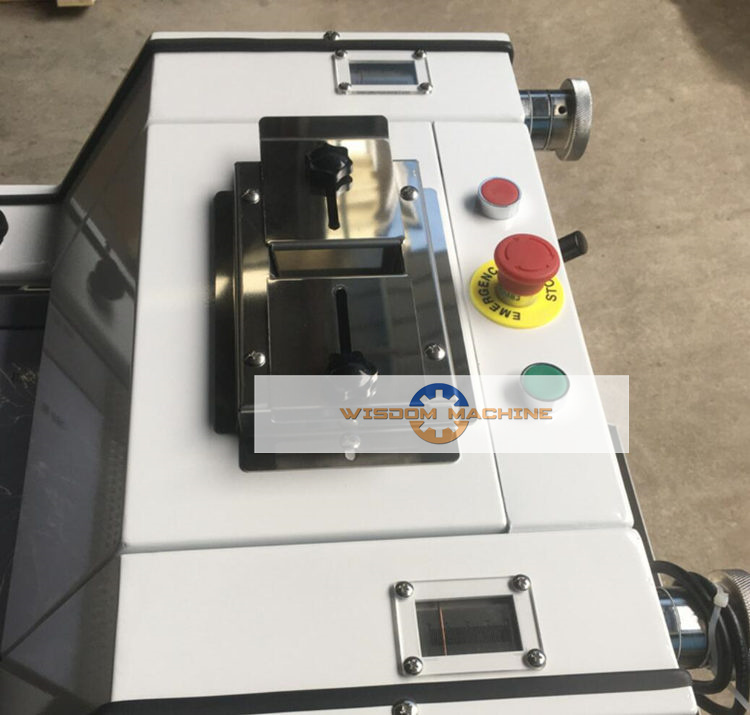

4. Simple operation, just press the switch button

The Cheap Loaf Toast Bread Dough Molding Making Machine is a machine that rolls the dough, fully exhausts the rolled dough, has a certain stretchability, and has a good moisturizing effect.

It is mainly used for the shaping of bread to maintain a certain shape of the bread, and can be used to make toast bread, Philippine bread or other fancy pastries and cakes that need to be shaped and rolled.

Cheap Loaf Toast Bread Dough Molding Making Machine Features:

1. Oil-immersed design, the pressure roller is hard-bonded, it does not stick to the surface and is not easy to be scratched.

2. The speed is fast, low noise, and the length of the dough can be adjusted.

3. Good ventilation, fully elongated dough.

4. The finished product has good thermal insulation and good organization, and it has more circles than the general shaping machine.

Cheap Loaf Toast Bread Dough Molding Making Machine Parameter:

|

model

|

280

|

|

power

|

0.75kw

|

|

dough weight

|

30-350g

|

|

moulding thickness

|

1.5-15mm

|

|

size

|

1300*665*1050mm

|

|

weight

|

145kg

|

Cheap Loaf Toast Bread Dough Molding Making Machine Daily Care and Maintenance

1. After going to work, the equipment should be tested with no load, and after confirming that there is no abnormality in the equipment, the official work will begin;

2. Put the dough into the feeding port, the dough should not be too hard, and the hard dough that has not been thawed should not be used, otherwise the service life of the equipment will be affected;

3. Before leaving get off work every day, clean the surface of the conveyor belt and the pressure roller. The residual dough at both ends of the pressure roller should be taken out in time, otherwise the flour will enter the rolling bearing and other moving parts, which will accelerate the wear of the machine parts and burn out the rolling bearing;

4. To clean the machine, please wipe it with a rag, but do not rinse it with a water pipe;

5. Untrained personnel are strictly prohibited to operate the machine;

6. Pay attention to the rotation direction of the pressing roller when the machine is new or reinstalled. The dough is fed from the top and sent out from the bottom is normal;

Cheap Loaf Toast Bread Dough Molding Making Machine Daily Care and Maintenance

1. After going to work, the equipment should be tested with no load, and after confirming that there is no abnormality in the equipment, the official work will begin;

2. Put the dough into the feeding port, the dough should not be too hard, and the hard dough that has not been thawed should not be used, otherwise the service life of the equipment will be affected;

3. Before leaving get off work every day, clean the surface of the conveyor belt and the pressure roller. The residual dough at both ends of the pressure roller should be taken out in time, otherwise the flour will enter the rolling bearing and other moving parts, which will accelerate the wear of the machine parts and burn out the rolling bearing;

4. To clean the machine, please wipe it with a rag, but do not rinse it with a water pipe;

5. Untrained personnel are strictly prohibited to operate the machine;

6. Pay attention to the rotation direction of the pressing roller when the machine is new or reinstalled. The dough is fed from the top and sent out from the bottom is normal;